Description

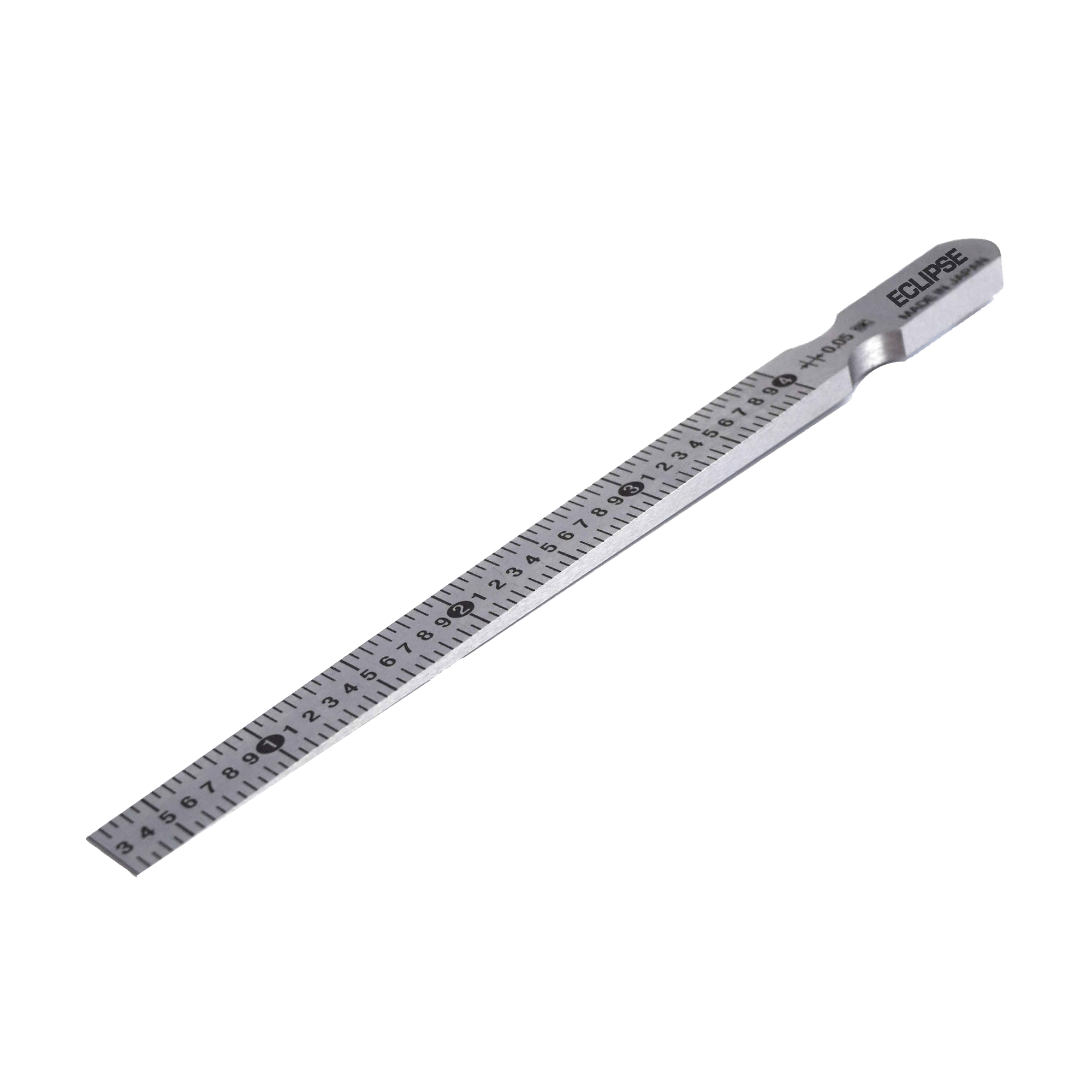

THIS PRODUCT: One Side Graduated Imperial 0.010″ to 0.150″, Other Side Graduated Metric 0.3mm to 4mm, Ideal For Measuring Gaps and Slots When Setting Machinery.

IN GENERAL: A taper gauge, also known as a taper measuring gauge or taper angle gauge, is a precision measuring tool designed to determine the angle or degree of taper on various objects, particularly in engineering, machining, and metalworking applications. It helps determine the slope or taper of a surface or object accurately. Here’s a brief description of a taper gauge and some common uses:

- Structure: A taper gauge typically consists of a thin, flat, or wedge-shaped piece of metal or other durable material. It is usually calibrated with graduations or markings that indicate the degree or angle of taper.

- Graduations: Taper gauges can have different types of markings, such as degrees, millimeters, or inches, depending on the measurement system used. Some taper gauges feature a scale that allows users to measure the taper over a specified distance.

- Design Variations: Taper gauges come in various designs, including straight-edge taper gauges, conical taper gauges, and cylindrical taper gauges. Each design is suitable for specific taper measurement needs.

Common Uses:

- Metalworking: Taper gauges are commonly used in metalworking, particularly in machining and lathe operations. Machinists and metalworkers use taper gauges to measure and verify the taper angles of turned parts and components, such as shafts, spindles, and drill bits.

- Engineering and Manufacturing: Engineers and manufacturers use taper gauges to ensure the precise taper of components in various industries, including aerospace, automotive, and manufacturing. This ensures that parts fit together correctly and meet quality standards.

- Woodworking: Taper gauges can be used in woodworking to measure and verify the taper angle of components such as table legs, chair legs, and spindles. Woodworkers use taper gauges to create matching and visually appealing pieces.

- Quality Control: Taper gauges play a critical role in quality control processes, where the correct taper angle of a product or component must be verified to meet specifications and ensure product reliability.

- Tool and Die Making: Taper gauges are essential tools for tool and die makers who need to verify the taper angles on cutting tools, punches, and dies to ensure accurate machining and stamping operations.

- Automotive and Engine Rebuilding: In the automotive industry and engine rebuilding workshops, taper gauges are used to measure the taper angles of cylinders, cylinder bores, and piston rings to ensure proper engine performance.

- Inspection and Maintenance: Taper gauges are useful for inspecting and maintaining tapered components such as valves, bearings, and mechanical seals in industrial equipment.

- Metal Tube and Pipe Manufacturing: Taper gauges are employed in the production of metal tubes and pipes to ensure consistent taper angles, which are essential for achieving tight connections in pipelines and plumbing systems.

- Educational and Training: Taper gauges are used in educational and training settings, such as technical schools and apprenticeship programs, to teach students about taper measurement and machining principles.

Taper gauges are crucial tools for ensuring the accuracy and precision of taper angles in a wide range of industries. They help maintain product quality, improve manufacturing efficiency, and ensure that components fit and function correctly.