Description

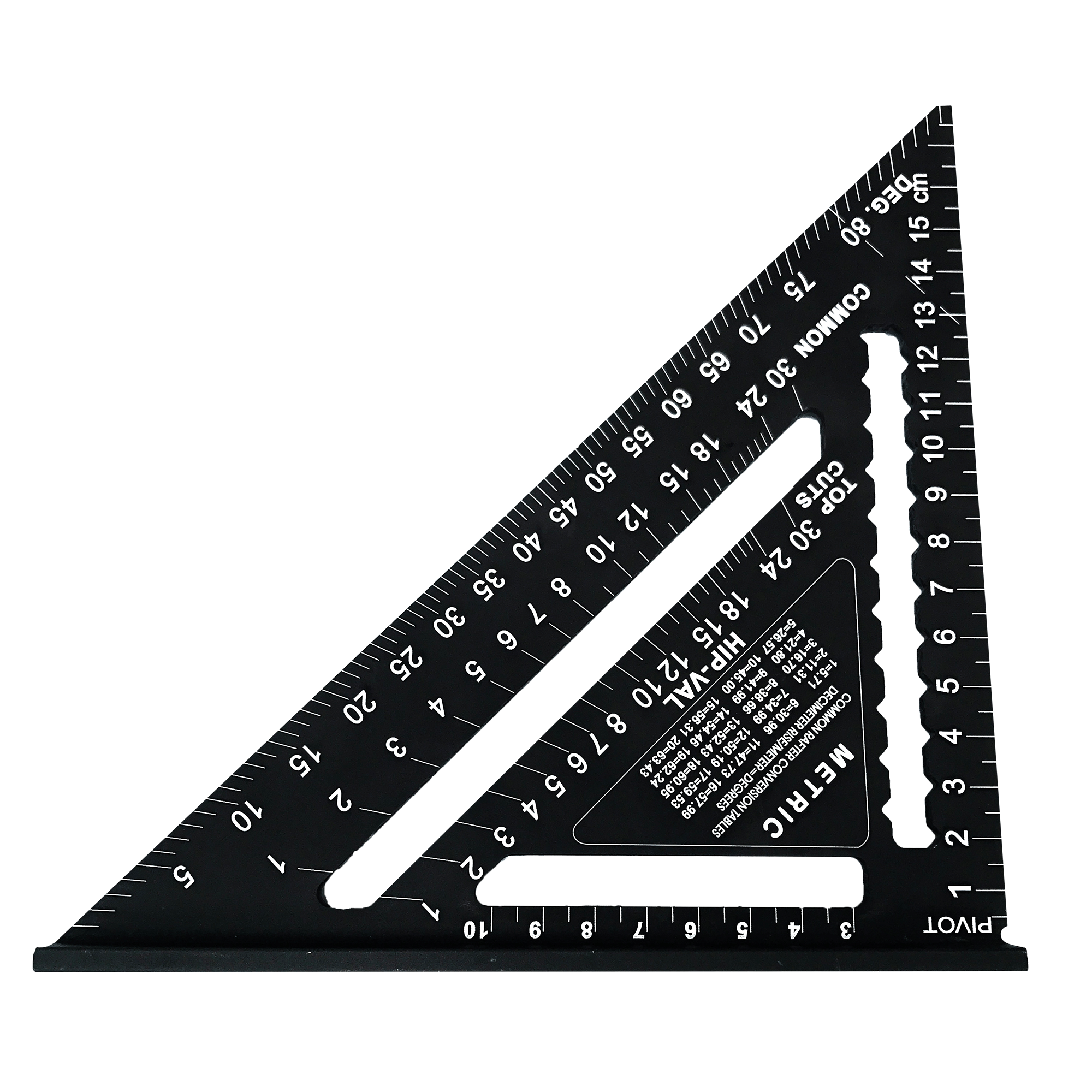

THIS PRODUCT: Sturdy Aluminium Construction, Stamped Conversion Tables, Thick Frame Designs Ensure Safe Use With A Saw or Knife Guide, Angles from 0 to 90 Degrees Can be Marked Quickly and Easily.

IN GENERAL: A rafter square, also known as a framing square, is a specialized measuring and layout tool used primarily in woodworking, carpentry, and construction for tasks related to roof framing and angle measurement. It is a versatile L-shaped tool that helps carpenters and builders make accurate measurements, mark angles, and create precise cuts when working on framing and roofing projects. Here’s a brief description of a rafter square and some common uses:

Description:

- Shape: A rafter square typically consists of an L-shaped, flat metal blade, with a long horizontal leg called the blade and a shorter vertical leg called the tongue. The blade and tongue meet at a perfect 90-degree angle to form an L-shaped tool.

- Measurement Markings: The blade of the rafter square is marked with various measurement scales, including imperial (inches) and sometimes metric (centimeters) graduations. These markings allow for measuring lengths, angles, and dimensions accurately.

- Angled Edge: The blade of the rafter square often features an angled edge, typically at 45 degrees, which is used to create and measure angles commonly used in roof framing and mitered cuts.

- Notches and Cutouts: Some rafter squares have notches, cutouts, or features designed for specific tasks, such as marking common rafter lengths and positions of roof pitches.

Common Uses:

- Roof Framing: Rafter squares are extensively used in roof framing to calculate and mark the lengths, angles, and cuts of rafters and common rafters, ensuring that they fit accurately into the roof structure.

- Layout of Stair Stringers: Carpenters and builders use rafter squares to lay out the dimensions and angles of stair stringers, which are the structural supports for stairs. The square helps ensure that each step is of consistent height and depth.

- Hip and Valley Rafters: When constructing hip and valley roofs, which involve more complex roof framing, a rafter square is used to mark the angles and lengths of hip and valley rafters accurately.

- Angle Measurement: The angled edge of the rafter square is employed to measure and mark specific angles, including 45-degree angles for mitered cuts commonly used in roofing and trim work.

- Square Cuts: Carpenters and woodworkers use the 90-degree angle of the rafter square to mark and create square cuts on various materials, such as lumber and plywood.

- Layout and Marking: Rafter squares are essential tools for laying out and marking cut lines, angles, and dimensions on various materials during construction and woodworking projects.

- Checking Squareness: Builders use rafter squares to check for squareness in buildings, structures, and assembled components, ensuring that corners, walls, and framing elements are properly aligned.

- DIY and Home Improvement: DIY enthusiasts and homeowners use rafter squares for various projects, including building sheds, pergolas, and decks, where precise angle measurements and layout are crucial.

- Quality Control: In manufacturing and quality control, rafter squares are used to verify the accuracy and precision of machined or fabricated components, especially in cases involving angles and lengths.

Rafter squares are essential tools for professionals and hobbyists in carpentry, construction, and woodworking, particularly when working on projects involving roofs, framing, and angled cuts. They provide accurate measurements, angles, and layout references, ensuring that structural and woodworking elements fit together accurately and securely.